Volko Supply

Long Island's premier

slate & tile supply house for 60+ years!

1-800-685-8263

|

Volko Supply Long Island's premier slate & tile supply house for 60+ years! |

1-800-685-8263 |

| Slate Tools Home | Slate Roofing History & Repair | Volko FAQ's | Slate Roofing Tools | www.volko.com | Sitemap |

Jeffrey S. Levine

�History of Slate Use

�Character and Detailing

�Where Does Slate Come From?

�Deterioration of Slate and Slate Roofs

�Repairing Slate Roofs

�The Replacement of Deteriorated Roofs

�Maintenance

�Conclusion

Slate is one of the most aesthetically pleasing and durable of all roofing materials. It is indicative at once of the awesome powers of nature which have formed it and the expertise and skill of the craftsman in handshaping and laying it on the roof. Installed properly, slate roofs require relatively little maintenance and will last 60 to 125 years or longer depending on the type of slate employed, roof configuration, and the geographical location of the property. Some slates have been known to last over 200 years. Found on virtually every class of structure, slate roofs are perhaps most often associated with institutional, ecclesiastical, and government buildings, where longevity is an especially important consideration in material choices. In the slate quarrying regions of the country, where supply is abundant, slate was often used on farm and agricultural buildings as well.

Because the pattern, detailing, and craftsmanship of slate roofs are important design elements of historic buildings, they should be repaired rather than replaced whenever possible. The purpose of this Preservation Brief is to assist property owners, architects, preservationists, and building managers in understanding the causes of slate roof failures and undertaking the repair and replacement of slate roofs. Details contributing to the character of historic slate roofs are described and guidance is offered on maintenance and the degree of intervention required at various levels of deterioration.

The relatively large percentage of historic buildings roofed with slate during the late nineteenth and early twentieth centuries means that many slate roofs, and the 60 to 125 year life span of the slates most commonly used, may be nearing the end of their serviceable lives at the end of the twentieth century. Too often, these roofs are being improperly repaired or replaced with alternative roofing materials, to the detriment of the historic integrity and appearance of the structure. Increased knowledge of the characteristics of slate and its detailing and installation on the roof can lead to more sensitive interventions in which original material is preserved and the building's historic character maintained. Every effort should be made to replace deteriorated slate roofs with new slate and to develop an effective maintenance and repair program for slate roofs that can be retained.

Although slate quarrying was not common in the United States until the latter half of the nineteenth century, slate roofing is known to have been used prior to the Revolution. Archeological excavations at Jamestown, Virginia,have unearthed roofing slate in strata dating from 1625-1650 and 1640-1670. Slate roofs were introduced in Boston as early as 1654 and Philadelphia in 1699. Seventeenth century building ordinances of New York and Boston recommended the use of slate or tile roofs to ensure fireproof construction.

Architectural pattern books of the mid-19th century awakened Americans to the availability and quality of slate for roofing purposes. Drawing: Design XX, "A French Roof House," in A.J. Downing's Victorian Cottage Residences. |

In the early years of the Colonies, nearly all roofing slate was imported from North Wales. It was not until 1785 that the first commercial slate quarry was opened in the United States, by William Docher in Peach Bottom Township, Pennsylvania. Production was limited to that which could be consumed in local markets until the middle of the nineteenth century. Knowledge of the nation's abundant stone resources was given commercial impetus at this time by several forces, including a rapidly growing population that demanded housing, advances in quarrying technology, and extension of the railroad system to previously inaccessible markets. Two additional factors helped push the slate industry to maturity: the immigration of Welsh slate workers to the United States and the introduction of architectural pattern and style books. Slate production increased dramatically in the years following the Civil War as quarries were opened in Vermont, New York, Virginia, and Lehigh and Northampton Counties, Pennsylvania. By 1876, roofing slate imports had all but dried up and the United States became a net exporter of the commodity.

The U.S. roofing slate industry reached its highest point in both quantity and value of output in the period from 1897 to 1914. In 1899, there were over 200 slate quarries operating in 13 states, Pennsylvania historically being the largest producer of all. The decline of the U.S. roofing slate industry began c.1915 and resulted from several factors, including a decline in skilled labor for both the fabrication and installation of slate and competition from substitute materials, such as asphalt shingles, which could be mass produced, transported and installed at a lower cost than slate. Only recently, with the increasing popularity of historic preservation and the recognition of the superiority of slate over other roofing materials, has slate usage begun to increase.

During some periods of architectural history, roof design has gone far beyond the merely functional and contributed much to the character of buildings. Roofs, by their compelling forms, have defined styles and, by their decorative patterns and colors, have imparted both dignity and beauty to buildings. The architectural styles prevalent during the latter half of the nineteenth and early twentieth centuries placed strong emphasis on prominent roof lines and greatly influenced the demand for slate. Slate, laid in multicolored decorative patterns, was particularly well suited to the Mansard roofs of the Second Empire style, the steeply pitch roofs of the Gothic Revival and High Victorian Gothic styles, and the many prominent roof planes and turrets associated with the Queen Anne style. The Tudor style imitated the quaint appearance of some English slates which, because of their granular cleavage, are thick and irregular. These slates were often laid in a graduated pattern, with the largest slates at the eaves and the courses diminishing in size up the roof slope, or a textural pattern. Collegiate Gothic style buildings, found on many university campuses, were often roofed with slate laid in a graduated pattern.

This graduated slate roof is composed of large, thick slates at the eave which are reduced in size and thickness as the slating progresses to the ridge. Photo: Jeffrey S. Levine. |

The configuration, massing, and style of historic slate roofs are important design elements that should be preserved. In addition, several types of historic detailing were often employed to add visual interest to the roof essentially elevating the roof to the level of an ornamental architectural element. When repairing or replacing a slate roof, original details affecting its visual character should be retained.

Before repairing or replacing an existing slate roof, it is important to document the existing conditions and detailing of the roof using written, visual, and physical evidence so that original features can be identified and preserved. Documentation should continue through the repair or replacement process as significant details, long obscured, are often rediscovered while carrying out these activities. Local histories, building records, old receipts and ledgers, historic photographs, sketches, and paintings, shadow lines and nail hole patterns on the roof deck, and bits of historic material left over from previous interventions (often found in eave cavities) are all useful sources of information which can be of help in piecing together the original appearance of the roof. Size, shape, color, texture, exposure, and coursing are among the most important characteristics of the original slates which should be documented and matched when repairing or replacing an historic slate roof.

Historically, three types of slate roofing--standard, textural, and graduated-were available according to the architectural effect desired. Standard grade slate roofs were most common. These are characterized by their uniform appearance, being composed of slates approximately 3/16" (0.5cm) thick, of consistent length and width, and having a smooth cleavage surface. Thirty different standard sizes were available, ranging from 10" (25cm) x 6" to 24" x 14" (15cm x 61cm x 35cm). The slates were laid to break joints and typically had square ends and uniform color and exposure. Patterned and polychromatic roofs were created by laying standard slates of different colors and shapes on the roof in such a way as to create sunbursts, flowers, sawtooth and geometric designs, and even initials and dates. On utilitarian structures, such as barns and sheds, large gaps were sometimes left between each slate within a given course to reduce material and installation costs and provide added ventilation for the interior.

Textural slate roofs incorporate slates of different thicknesses, uneven tails, and a rougher texture than standard slates. Textural slate roofs are perhaps most often associated with Tudor style buildings where slates of different colors are used to enhance the effect.

Graduated slate roofs were frequently installed on large institutional and ecclesiastical structures. The slates were graduated according to thickness, size, and exposure, the thickest and largest slates being laid at the eaves and the thinnest and smallest at the ridge. Pleasing architectural effects were achieved by blending sizes and colors.

Valleys are formed at the internal angle of two roofing slopes. Flashing is often placed under the slate to increase moisture protection at this vulnerable joint. Photo: Jeffrey S. Levine. |

Detailing at the hips, ridges and valleys provided added opportunity to ornament a slate roof. Hips and ridges can be fashioned out of slate according to various traditional schemes whereby the slates are cut and overlapped to produce a watertight joint of the desired artistic effect. Traditional slate ridge details are the saddle ridge, strip saddle rid~e and comb ridge, and for hips, the saddle hip, mitered hip Boston hip, and fantail hip. A more linear effect was achieved by covering the ridges and hips with flashing called "cresting" or "ridge roll" formed out of sheet metal, terra cotta, or even slate. Snow guards, snow boards, and various types of gutter and rake treatments also contributed to the character of historic slate roofs.

Two types of valleys were traditionally employed, the open valley and the closed valley. The open valley is lined with metal over which slates lap only at the sides. Closed valleys are covered with slate and have either a continuous metal lining or metal flashing built in with each course. Open valleys are easier to install and maintain, and are generally more watertight than closed valleys. Round valleys are a type of closed valley with a concave rather than Vshaped section. Given the broader sweep of the round valley, it was not uncommon for roofers to interweave asphalt saturated felts rather than copper sheet in the coursing in order to cut costs.

Although principally associated with graduated and textural slate roofs, round valleys were infrequently employed due to the difficulty and expense of their installation.

Common types of sheathing used include wood boards, wood battens, and, for fireproof construction on institutional and government buildings, concrete or steel. Solid wood sheathing was typically constructed of tongue and groove, square edged, or shiplapped pine boards of 1" (2.5 cm) or 1-1/4" (3 cm) nominal thickness. Boards from 6" (15 cm) to 8" (20 cm) wide and tongue and groove boards were generally preferred as they were less likely to warp and curl.

Wood battens, or open wood sheathing, consisted of wood strips, measuring from 2" (5 cm) to 3" (7.5 cm) in width, nailed to the roof rafters. Spacing of the battens depended on the length of the slate and equaled the exposure. Slates were nailed to the batten that transected its midsection. The upper end of the slate rested at least �" (1.25 cm) on the batten next above. Open wood sheathing was employed primarily on utilitarian, farm, and agricultural structures in the North and on residential buildings in the South where the insulating value of solid wood sheathing was not a strict requirement. To help keep out dust and wind driven rain on residential buildings, mortar was often placed along the top and bottom edge of each batten, a practice sometimes referred to as torching.

Eave details include snow guards, snow boards, and gutter treatments. Snow guards are generally used in areas where the ice and snow accumulate to avoid dangerous slides from the roof. Photo: Jeffrey S. Levine. |

Steel angles substituted for the wood battens in fireproof construction. The slates were secured using wire wrapped around the steel angle, where it was twistedoff tight. Alternately, any of a variety of special fasteners patented over the years could have been used to attach the slate to the steel angle. On roofs with concrete decks, slates were typically nailed to wood nailing strips embedded in the concrete.

Beginning in the late nineteenth century, asphalt saturated roofing felt was installed atop solid wood sheathing. The felt provided a temporary, watertight roof until the slate could be installed atop it. Felt also served to cushion the slates, exclude wind driven rain and dust, and ease slight unevenness between the sheathing boards.

Slate was typically laid in horizontal courses starting at the eaves with a standard headlap of 3" (7.5 cm) (Figure 10). Headlap was generally reduced to 2" (5 cm) on Mansard roofs and on particularly steep slopes with more than 20" (50 cm) of rise per 12" (30 cm) of run. Conversely, headlap was increased to 4" (10 cm) or more on low pitched roofs with a rise of 8" (20 cm) or less per 12" (30 cm) of horizontal run. The minimum roof slope necessary for a slate roof was 4" (10 cm) of rise per 12" (30 cm) of run.

Slate is a fine grained, crystalline rock derived from sediments of clay and fine silt which were deposited on ancient sea bottoms. Superimposed materials gradually consolidated the sedimentary particles into bedded deposits of shale. Mountain building forces subsequently folded, crumpled, and compressed the shale. At the same time, intense heat and pressure changed the original clays into new minerals such as mica, chlorite, and quartz. By such mechanical and chemical processes bedded clays were transformed, or metamorphosed, into slate, whole geologic ages being consumed in the process. Slates vary in composition, structure, and durability because the degree to which their determinant minerals have been altered is neither uniform nor consistent.

These traditional slater's tools are used to cut and trim, hammer, measure, and rip out nails. Photo: Jeffrey S. Levine. |

The adaptation of slate for roofing purposes is inextricably linked to its genesis. The manufacturing processes of nature have endowed slate with certain commercially amenable properties which have had a profound influence on the methods by which slate is quarried and fabricated, as well as its suitability for use as a roofing tile.

Slate roofing tiles are still manufactured by hand using traditional methods in a five step process: cutting, sculping, splitting, trimming, and hole punching. In the manufacturing process, large, irregular blocks taken from the quarry are first cut with a saw across the grain in sections slightly longer than the length of the finished roofing slate. The blocks are next sculped, or split along the grain of the slate, to widths slightly larger than the widths of finished slates. Sculping is generally accomplished with a mallet and a broadfaced chisel, although some types of slate must be cut along their grain. In the splitting area, the slightly oversized blocks are split along their cleavage planes to the desired shingle thickness. The splitter's tools consist of a wooden mallet and two splitting chisels used for prying the block into halves and repeating this process until the desired thinness is reached. The last two steps involve trimming the tile to the desired size and then punching two nail holes toward the top of the slate using a formula based on the size and exposure of the slate.

Minerals, the building blocks of rocks, through their characteristic crystalline structures define the physical properties of the rocks which they compose. Slate consists of minerals that are stable and resistant to weathering and is, therefore, generally of high strength, low porosity, and low absorption. The low porosity and low absorption of slate mitigate the deleterious action of frost on the stone and make it well adapted for roofing purposes. The two most important structural properties of slate are cleavage and grain.

The metamorphic processes of geologic change necessary to produce slate are dependent upon movements in the earth's crust and the heat and pressure generated thereby. For this reason, slate is found only in certain mountainous regions. The most economically important slate deposits in this country lie in the Mid-Atlantic and Northeastern states transversed by or bordering on the Appalachian Mountain chain. Variations in local chemistry and conditions under which the slate was formed have produced a wide range of colors and qualities and ultimately determine the character of the slate found in these areas.

Slate is available in a variety of colors. The most common are grey, blue-grey, black, various shades of green, deep purple, brick red, and mottled varieties. The presence of carbonaceous matter, derived from the decay of marine organisms on ancient sea floors, gives rise to the black colored slates. Compounds of iron generate the red, purple, and green colored slates.

Generally, the slates of Maine, Virginia, and the Peach Bottom district of York County, Pennsylvania are deep blue-black in color. Those of Virginia have a distinctive lustrous appearance as well due to their high mica content. The slates of Lehigh and Northampton Counties, Pennsylvania, are grayish-black in color. Green, red, purple, and mottled slates derive from the New York-Vermont district. The slate producing region of New York, which centers around Granville and Middle Granville, is particularly important because it contains one of the few commercial deposits of red slate in the world.

Slates are also classified as fading or unfading according to their color stability. Fading slates change to new shades or may streak within a short time after exposure to the atmosphere due to the presence of finegrained disseminated pyrite. For example, the "weathering green" or "seagreen" slates of New York and Vermont are grayish green when freshly quarried. Upon exposure, from 20% to 60% of the slates typically weather to soft tones of orange-brown, buff, and gray while the others retain their original shade. Slates designated as unfading maintain their original colors for many years.

Color permanence generally provides no indication of the durability of slate. Rather, time has shown that the Vermont and New York slates will last about 125 years; Buckingham Virginia slates 175 years or more; and Pennsylvania SoftVein slates in excess of 60 years; Pennsylvania HardVein slates and Peach Bottom slates, neither of which is still quarried, had life spans of roughly 100 and at least 200 years respectively. The life spans provided should be used only as a general guide in determining whether or not an existing slate roof is nearing the end of its serviceable life.

Ribbons are visible as bands on the cleavage face of slate and represent geologic periods during which greater amounts of carbonaceous matter, calcite, or coarse quartz particles were present in the sediment from which the slate was formed. Ribbons typically weather more and were most common in Pennsylvania slate quarries. As they were not as durable as clear slates, ribbon slate is no longer manufactured for roofing purposes. Mottled grey slates from Vermont are the closest match for Pennsylvania ribbon slate available today.

In recent years, slates from China, Africa, Spain and other countries have begun to be imported into the United States, primarily for distribution on the West Coast. The use of imported slates should probably be limited to new construction since their colors and textures often do not match those of U.S. slate.

The white blotches on these Pennsylvania Soft-Vein slates indicate areas where gypsum is leaching out onto the surfaces of the slates. Photo: Jeffrey S. Levine. |

The durability of a slate roof depends primarily on four factors: the physical and mineralogical properties of the slate; the way in which it is fabricated; installation techniques employed; and, regular and timely maintenance. The first three of these factors are examined below. The maintenance and repair of slate roofs are discussed in later sections of this Brief.

The natural weathering of roofing slate manifests itself as a slow process of chipping and scaling along the cleavage planes. Paper thin laminations flake off the surface of the slate and the slate becomes soft and spongy as the inner layers begin to come apart, or delaminate. The nature of the sound given off by a slate when tapped with one's knuckles or slating hammer is a fair indication of its condition. Highgrade slate, when poised upon the fingertips and struck, will emit a clear, solid sound. Severely weathered slates are much less sonorous, and give off a dull thud when tapped.

The weathering of slate is chiefly due to mineral impurities (primarily calcite and iron sulfides) in the slate which, in concert with alternating wet/dry and hot/cold cycles, react to form gypsum. Because gypsum molecules take up about twice as much volume as calcite molecules, internal stresses result from the reaction, causing the slate to delaminate. This type of deterioration is as prominent on the underside of the roof as on the exposed surface due to the leaching and subsequent concentration of gypsum in this area. Consequently, deteriorated roofing slates typically cannot be flipped over and reused.

Paper thin lamination can be seen flaking off this weathered, 120 year piece of Pennsylvania Hard-Vein slate. Photo: Jeffrey S. Levine. |

The chemical and physical changes which accompany slate weathering cause an increase in absorption and a decrease in both strength and toughness. The tendency of old, weathered slates to absorb and hold moisture can lead to rot in underlying areas of wood sheathing. Such rot can go undetected for long periods of time since, often, there is no accompanying leak. Due to their loss of strength, weathered slates are more prone to breakage, loss of corners, and cracking.

Slates with low calcite content tend to weather slowly. Dense slates, with low porosity, likewise decay slower than slates with equal calcite, but with a greater porosity. The pitch of a roof can also affect its longevity. The steeper the pitch, the longer the slate can be expected to last as water will run off faster and will be less likely to be drawn under the slates by capillary action or driven under by wind forces. Spires and the steep slopes of Mansard roofs often retain their original slate long after other portions of the roof have been replaced. Areas of a roof subject to concentrated water flows and ice damming, such as along eaves and valleys, also tend to deteriorate more rapidly than other areas of the roof.

View of these slates laid on open sheathing shows that delamination and flaking are just as bad or worse on the underside of slates as on the exposed surface. This is why most slates cannot be flipped over for reuse. Photo: Jeffrey S. Levine. |

Mechanical agents, such as thermal expansion and contraction and the action of frost, are subordinate in the weathering of slate, coming into play only after the slate has been materially altered from its original state by the chemical transformation of calcite to gypsum. The more rapid deterioration of slates found on roof slopes with the most severe exposure to the sun, wind, and rain (typically, but not always, a southern exposure) may be attributable to the combined result of the deleterious effects of impurities in the slate and mechanical agents. Atmospheric acids produce only negligible deterioration in roofing slate.

It is difficult to assess the procedures by which a piece of slate has been fabricated without visiting the quarry and observing the process first hand. The location and size of nail holes, grain orientation, the condition of corners, and the number of broken pieces are all things which may be observed in a shipment of slate to judge the quality of its fabrication. Nail holes should be clean and with a shallow countersink on the face of the slate for the nail head; grain oriented along the length of the slate; and, corners left whole. An allowance for 10% breakage in shipment is typically provided for by the quarry.

Installation problems often involve the improper nailing and lapping of slates. The nailing of slates differs from that of other roofing materials. Slate nails should not be driven tight as is the case with asphalt and wood shingles. Rather, they should be set such that the slate is permitted to hang freely on the nail shank. Nails driven too far will crack the slate and those left projecting will puncture the overlying slate. Nail heads left exposed accelerate roof deterioration by providing a point for water entry. Non-ferrous slater's nails, such as solid copper or stainless steel, should always be used since plain steel and galvanized nails will usually rust out long before the slate itself begins to deteriorate. The rusting of nineteenth century cut nails is a common cause of slate loss on historic roofs.

When joints are improperly broken (i.e., when slates lap the joints in the course below by less than 3" [7.5 cm]), it is possible for water to pass between the joints, through the nail holes and ultimately to the underlying felt, where it will cause deterioration and leaks to develop. Insufficient headlap can also result in leaks as water entering the joints between slates may have a greater tendency to be wind blown beyond the heads of the slates in the course below.

Occasionally, individual slates are damaged. This may be caused by falling tree limbs, ice dams in gutters, valleys, and chimney crickets, the weight of a workman walking on the roof, or a naturally occurring fault in the slate unit. Whatever the form of damage, if it is caught soon enough, the roof can usually be repaired or selectively replaced and deterioration mitigated.

The ability to lay slate properly so as to produce a watertight and aesthetically pleasing roof requires training, much practice, and the right tools. The installation and repair of slate roofs should be entrusted only to experienced slaters.

Broken, cracked, and missing slates should be repaired promptly by an experienced slater in order to prevent water damage to interior finishes, accelerated deterioration of the roof and roof sheathing, and possible structural degradation to framing members.

The damaged slate is first removed by cutting or pulling out its nails with a ripper. If steel cut nails, rather than copper nails, were used in laying the roof, adjacent slates may be inadvertently damaged or displaced in the ripping process, and these, too, will have to be repaired. If the slate does not slide out by itself, the pointed end of the ,slate hammer can be punched into the slate and the slate dragged out. A new slate, or salvaged slate, which should match the size, shape, texture, and weathered color of the old slate, is then slid into place and held in position by one nail inserted through the vertical joint between the slates in the course above and approximately one inch below the tail of the slate two courses above.

After removing the deteriorated slate and sliding the new slate into place, it is secured with a copper nail. A copper bib (shown here) is formed to protect the newly created nail hole. Finally, a slate hammer is used to push the bib in place over the nail head. Photo: Jeffrey S. Levine. |

To prevent water penetration through the newly created nail hole, a piece of copper with a friction fit, measuring roughly 3" (7.5 cm) in width and 8" (20 cm) in length, is slid lengthwise under the joint between the two slates located directly above the new slate and over the nail. Alternate methods for securing the replacement slate include the use of metal hooks, clips, and straps that are bent over the tail end of the slate. The application of roofing mastic or sealants to damaged slates should not be considered a viable repair alternative because these materials, though effective at first, will eventually harden and crack, thereby allowing water to enter.

Mastic also makes future repairs more difficult to execute, is unsightly, and, when applied to metal flashings, accelerates their corrosion.

When two or more broken slates lie adjacent to each other in the same course, or when replacing leaky valley flashings, it is best to form pyramids (i.e., to remove a diminishing number of slates from higher courses) to keep the number of bibs required to a minimum. When reinstalling the slates, only the top slate in each pyramid will need a bib. Slates along the sides of the pyramid will receive two nails, one above the other, along the upper part of its exposed edge.

When many slates must be removed to effect a repair, the sheathing should be checked for rotted areas and projecting nails. Plywood is generally not a good replacement material for deteriorated wood sheathing due to the relative difficulty of driving a nail through it (the bounce produced can loosen adjacent slates). Instead, new wood boards of similar width and thickness to those being replaced should be used. Because the nominal thickness of today's dimension lumber is slightly thinner than that produced in the past, it may be necessary to shim the new wood boards so that they lie flush with the top surface of adjacent existing sheathing boards. Pressure treated lumber is not recommended due to its tendency to shrink. This can cause the slates to crack and become displaced.

To permit proper re-laying of the slate, the new roof sheathing must be of smooth and solid construction. At least two nails should be placed through the new boards at every rafter and joints between the ends of the boards should occur over rafters. Insufficient nailing will cause the boards to be springy, making nailing of the slates difficult and causing adjacent slates to loosen in the process. Unevenness in the sheathing will show in the finished roof surface and may cause premature cracking of the slate. Roof sheathing in valleys and along hips, ridges, and eaves may be covered with waterproof membrane underlayment rather than roofing felt for added protection against leakage.

After a hurricane or other natural disaster, it may be necessary to stabilize a roof temporarily until materials can be obtained and a qualified roofing contractor hired. Significant slate roofs should not be stripped off and replaced with asphalt shingles. Photo: NPS files. |

In emergency situations, such as when severe hurricanes or tornadoes blow numerous slates off the roof, a temporary roof covering should be installed immediately after the storm to prevent further water damage to the interior of the building and to permit the drying out process to begin. Heavy gauge plastic and vinyl tarpaulins are often used for this purpose, though they are difficult to secure in place and can be blown off in high winds. Roll roofing, carefully stitched in to areas of the remaining roof, is a somewhat more functional solution that will allow sufficient time to document the existing roof conditions, plan repairs, and order materials.

Slate roof repair is viable for localized problems and damaged roofs with reasonably long serviceable lives remaining. If 20% or more of the slates on a roof or roof slope are broken, cracked, missing, or sliding out of position, it is usually less expensive to replace the roof than to execute individual repairs. This is especially true of older roofs nearing the end of their serviceable lives because even the most experienced slater will likely damage additional slates while attempting repairs. Depending on the age of the slate, its expected serviceable life, and the cause(s) of deterioration, it may or may not be cost effective to salvage slates. Where deteriorated nails or flashings are the cause of the roof failure, salvage of at least some slates should be possible for use in repairs. When salvaging slates, each must be sounded to discover cracks and faults and the degree to which it has weathered. It is usually wise to salvage slates when only a portion of the roof is to be replaced. In this way, the salvaged slates may be used for future repairs to the remaining sections of the roof.

Historic slate roofs should be repaired rather than replaced whenever possible. Before replacing a slate roof, check for isolated damage, corroded and worn flashings, leaky gutters, poor ventilation in the attic, and other possible sources of moisture. All too often slate roofs are mistakenly replaced when, in fact, they could have been effectively repaired. Deciding whether an historic slate roof should be repaired or replaced can be difficult and each roof must be judged separately.

If repair is not possible and a new slate roof must be installed, it is important to remember that more than just the replacement of the slate is involved. The old slate should be removed to prevent overloading of the roof timbers. Stripping should be done in sections, with felt installed, to avoid exposing the entire subroof to the weather. ln the process, rotted wood sheathing should be replaced and the roof timbers checked for signs of stress including deflection, cracking, and twisting. If such conditions are found, a structural engineer experienced in working with older buildings should be consulted. Other repairs, such as chimney repointing, which may require access to the roof should be completed before the new roof is put on.

Drawings and specifications for a new slate roof should be prepared by a restoration architect, especially if the project is going to be competitively bid or if the roof is particularly complex. Standard specifications, like those published in 1926 by the National Slate Association may be used as a basis for developing specifications appropriate for a particular project. The specifications and drawings should contain all the information necessary to replicate the original appearance of the roof as closely as possible. Certain changes may have to be accepted, however, since several types of slate once prominent in this country, such as ribbon slate, are no longer quarried. It is wise to anticipate the replacement of older roofs so that proper planning can be undertaken and financial resources set aside, thereby, reducing the likelihood of rash last minute decisions.

Prior to a replacing a roof, historical documentation is gathered (such as photo documentation) to determine the roof configuration. Photo: NPS files. |

Roofing slate is sold by the square in the United States. One square is enough to cover 100 square feet (13.3 square meters) of plain roof surface when laid with a standard headlap of 3" (7.5cm). When ordering slate, considerable lead time should be allowed as delivery may take anywhere from 4 to 12 weeks and even as long as 1 year for special orders. Orders for random widths of a particular slate can generally be filled more quickly than orders for fixed widths. Once on site, slates should be stored on edge, under cover on pallets.

A roof and its associated flashings, gutters, and downspouts function as a system to shed water. Material choices should be made with this in mind. For example, use a single type of metal for all flashings and the rainwater conductor system to avoid galvanic action. Choose materials with life spans comparable to that of the slate, such as nonferrous nails. Use heavier gauge flashings or sacrificial flashings in areas that are difficult to access or subject to concentrated water flows.

Flashings are the weakest point in any roof. Given the permanence of slate, it is poor economy to use anything but the most durable of metals and the best workmanship for installing flashings. Copper is one of the best flashing materials, and along with terne, is most often associated with historic slate roofs. Copper is extremely durable, easily worked and soldered, and requires little maintenance. Sixteen ounce copper sheet is the minimum weight recommended for flashings. Lighter weights will not endure the erosive action of dust and grit carried over the roof by rain water. Heavier weight, 20 oz. (565 grams) or 24 oz. (680 grams), copper should be used in gutters, valleys, and areas with limited accessibility. Lead coated copper has properties similar to copper and is even more durable due to its additional lead coating. Lead coated copper is often used in restoration work.

Terne is a less desirable flashing material since it must be painted periodically. Terne coated stainless steel (TCS) is a modernday substitute for terne. Although more difficult to work than terne, TCS will not corrode if left unpainted; a great advantage, especially in areas that are difficult to access.

Once a metal is chosen, it is important to use it throughout for all flashings, gutters, downspouts, and metal roofs. Mixing of dissimilar metals can lead to rapid corrosion of the more electronegative metal by galvanic action. Where flashings turn up a vertical surface, they should be covered with a cap flashing. Slates which overlap metal flashings should be nailed in such a manner as to avoid puncturing the metal. This may be accomplished by punching a second hole about 2" (5cm) above the existing hole on the side of the slate not overlapping the metal flashing. It is important that holes be punched from the back side of the slate. In this way, a shallow countersink is created on the face of the slate in which the head of the nail may sit.

The use of artificial, mineral fiber slate is not recommended for restoration work since its rigid appearance is that of a manmade material and not one of nature. Artificial slates may also have a tendency to fade over time. And, although artificial slate costs less than natural slate, the total initial cost of an artificial slate roof is only marginally less than a natural slate roof. This is because all the other costs associated with replacing a slate roof, such as the cost of labor, flashings, and tearingoff the old roof, are equal in both cases. Over the long term, natural slate tends to be a better investment because several artificial slate roofs will have to be installed during the life span of one natural slate roof.

Roofing felt is being installed over the decking; a rubberized membrane is used selctively at the eaves and under some flashing. Photo: NPS files. |

Clear roof expanses can be covered by an experienced slater and one helper at the rate of about two to three squares per day. More complex roofs and the presence of chimneys, dormers, and valleys can bring this rate down to below one square per day. One square per day is a good average rate to use in figuring how long a job will take to complete. This takes into account the installation of flashings and gutters and the setup and breakdown of scaffolding. Tear-off of the existing roof will require additional time.

The following guideline is provided to assist in the repair/replace decision making process:

1. Consider the age and condition of the roof versus its expected serviceable life given the type of slate employed.

2. Calculate the number of damaged and missing slates. Is the number less than about 20%? Is the roof generally in good condition? If so, the roof should be evaluated for repair rather than replacement. Also, keep in mind that the older a roof becomes, the more maintenance it will likely require.

3. Determine if there are active leaks and what their source may be. Do not assume the slates are leaking. Gutters, valleys and flashings are more likely candidates. "False leaks" can be caused by moisture condensation in the attic due to improper ventilation.

4. Check the roof rafters and sheathing for moisture stains. Poke an awl into the wood to determine if it is rotted. Remember that very old, delaminating slates will hold moisture and cause adjacent wood members to deteriorate even if there are no apparent leaks.

5. Are many slates sliding out of position? If so, it may be that ferrous metal fasteners were used and that these are corroding, while the slates are still in good condition. Salvage the slates and relay them on the roof. If the slates have worn around the nails holes, it may be necessary to punch new holes before relaying them.

6. Consider the condition of the roof's flashings. Because slate is so durable, metal flashings often wear out before the slate does. Examine the flashings carefully. Even the smallest pinhole can permit large quantities of water to enter the building. Is the deterioration of the slate uniform? Often this is not the case. It may be that only one slope needs replacement and the other slopes can be repaired. In this way, the cost of replacement can be spread over many years.

7. Press down hard on the slates with your hand. Sound slates will be unaffected by the pressure. Deteriorated slates will feel brittle and will crack. Tap on slates that have fallen out or been removed. A full, deep sound indicates a slate in good condition, while a dull thud suggests a slate in poor condition.

8. Are new slates readily available? Even if replacement is determined to be necessary, the existing roof may have to be repaired to allow time for documentation and the ordering of appropriate replacement slates.

Note: measurements in this publication are given in both U.S. Customary System and International (Metric) System for comparative purposes. Metric conversions are in some cases approximate and should not be relied upon in preparing technical specifications.

Given the relatively high initial cost of installing a new slate roof, it pays to inspect its overall condition annually and after several storms. For safety reasons, it is recommended that building owners and maintenance personnel carry out roof surveys from the ground using binoculars or from a cherry picker. Cracked, broken, misaligned, and missing slates and the degree to which delamination has occurred should be noted, along with failed flashings (pin holes, open seams, loose and misaligned elements, etc.) and broken or clogged downspouts. A roof plan or sketch and a camera can aid in recording problems and discussing them with contractors. In the attic, wood rafters and sheathing should be checked for water stains and rot. Critical areas are typically near the roof plate and at the intersection of roof planes, such as at valleys and hips. Regular maintenance should include cleaning gutters at least twice during the fall and once in early spring, and replacing damaged slates promptly. Every five to seven years inspections should be conducted by professionals experienced in working with slate and steep slopes. Good record keeping, in the form of a log book and the systematic filing of all bills and samples, can help in piecing together a roof's repair history and is an important part of maintenance.

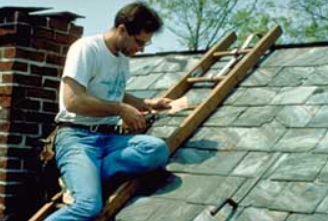

As part of regular maintenance, an attempt should be made to keep foot traffic off the roof. If maintenance personnel, chimney sweeps, painters, or others must walk on the roof, it is recommended that ladders be hooked over the ridge and that the workmen walk on the ladders to better distribute their weight. If slates are to be walked on, it is best to wear soft soled shoes and to step on the lowermiddle of the exposed portion of the slate unit.

Slate roofs are a critical design feature of many historic buildings that cannot be duplicated using substitute materials. Slate roofs can, and should be, maintained and repaired to effectively extend their serviceable lives. When replacement is necessary, details contributing to the appearance of the roof should be retained. High quality slate is still available from reputable quarries and, while a significant investment, can be a cost effective solution over the long term.

Copper And Brass Research Association. Copper Flashings. 2nd ed. New York: Copper And Brass Research Association, 1925.

Dale, T. Nelson, and others. Slate in The United States, Bulletin 586. Washington, D C.: U S. Department of the Interior, United States Geological Survey, 1914.

Heim, David. "Roofing With Slate." Fine Homebuilding, No. 20 (April/May 1984): 3843.

Levine, Jeffrey S. "Slate Roofs For Historic Religious Buildings." Inspired. Philadelphia: Philadelphia Historic Preservation Corporation, 1987.

____________, "Slate Quarrying and Shingle Manufacture" Fine Homebuilding No. 71 (Jan. 1992): 6468.

McKee, Harley 1. "Slate Roofing." APT Bulletin, Vol. 2, Nos. 1-2 (1970): 7784.

National Slate Association. Slate Roofs. 1925 Reprint. Fair Haven, Vermont: Vermont Structural Slate Co., Inc., 1977.

Pierpont, Robert N. "Slate Roofing." APT Bulletin, Vol. 19, No. 2 (1987): 1023.

Sweetser, Sarah M. Preservation Briefs 4: Roofing for Historic Buildings. Washington, D.C.: U.S. Department of the Interior, Technical Preservation Services Division, 1975.

The author, Jeffrey S. Levine, is an Architectural Conservator with John Milner Associates, Inc., and gratefully acknowledges the technical review of this publication by the following: Russel Watsky, Watsky Associates; Kenton Lerch, The Structural Slate Company; Matt Millen, Millen Roofing Co.; Alex Echeguren, Echeguren Slate Company; Bill Markcrow, Vermont Structural Slate Company; and Dick Naslund, Department of Geological Sciences, State University of New York at Binghamton. In addition, invaluable comments were provided by Sharon Park, Doug Hicks and Michael J. Auer, National Park Service; Suzanne Barucco, Martin Jay Rosenblum, R.A. & Associates; and Fred Walters, John Milner Associates, Inc.

Sharon C. Park, AIA, Senior Historical Architect, Preservation Assistance Division, National Park Service, is credited with directing the development of this publication and with its technical editorship.

Washington, D.C. September, 1992

Home page logo: Slate roof repair. Photo: Jeffrey S. Levine.

This publication has been prepared pursuant to the National Historic Preservation Act of 1966, as amended, which directs the Secretary of the Interior to develop and make available information concerning historic properties. Technical Preservation Services (TPS), Heritage Preservation Services Division, National Park Service prepares standards, guidelines, and other educational materials on responsible historic preservation treatments to a broad public.

KDW